Unique large-scale storage solution paves new way for offshore hydrogen production.

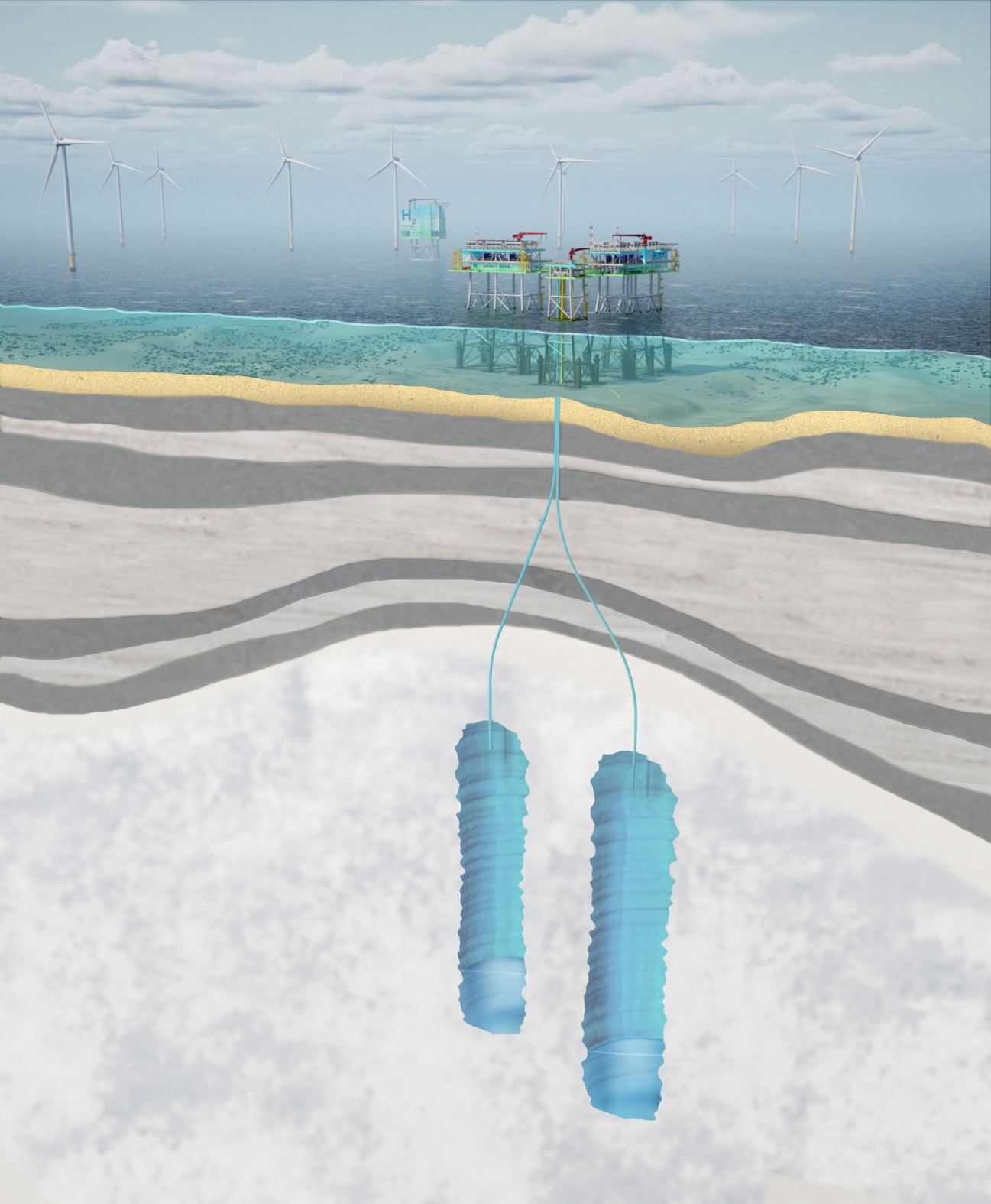

Tractebel and partner companies have developed the world’s first offshore infrastructure and processing facilities concept for the storage of hydrogen in offshore caverns. The design study, unveiled by Tractebel Overdick GmbH’s offshore experts, outlines an innovative solution for large-scale hydrogen storage on the high seas: a scalable offshore platform for the compression and storage of up to 1.2 million m³ of hydrogen. Underground salt caverns will be used as storage and buffer for the hydrogen produced offshore, before the gas is transported via the pipeline network to the onshore grid and finally to consumers and customers.

Meeting the hydrogen demands of the future

Green hydrogen from offshore wind energy is becoming an important component of the global energy transition, but current hydrogen production technologies will only make an effective contribution if production rates reach an industrial scale. Enormous amounts of hydrogen (H2) from renewable sources will be required to supply future H2 energy demands and offshore sites are key to industrial-scale production. Tractebel pioneered an innovative solution to address this demand in 2019, with the development of a unique offshore hydrogen platform concept, followed by an optimised, scalable version the following year. And now, Tractebel’s experts break new ground with the design of the world’s first offshore infrastructure and processing facilities concept for the storage of hydrogen in offshore caverns.

Infrastructure for hydrogen production on the high seas

This offshore platform complex consists of a wellhead platform for the operation of the caverns and a series of compression platforms that enable a staged increase in capacity. If required, the plant can also be expanded in the future by additional modules. The study assumes a capacity equivalent to converting 2 GW of green offshore wind power into hydrogen. Extensions and individual adaptations are possible at any time.

Offshore compression and storage hubs such as these can further increase the flexibility of upcoming offshore hydrogen production. As the compression effort decreases at the wind farms’ electrolysis plants, so too shall the cost for offshore hydrogen production sites in general. “Centralised offshore hydrogen hubs also facilitate the integration of smaller-scale hydrogen production, which is to be expected within the scope of capacity expansions while re-powering offshore wind farms in the future. At the same time, they offer an economically viable option, as the export and compression of hydrogen produced offshore can be bundled. This significantly reduces the overall costs for future projects,” says Klaas Oltmann, Director Business Development at Tractebel Overdick GmbH.

A powerful solution with a sustainable side effect

The newly designed storage and compressor platforms process 400,000 Nm3/h of hydrogen, which is stored in underground salt caverns at a pressure of up to 180 bar. These storage facilities buffer production peaks, optimise flow rates and therefore enable a more economical design of the export pipeline.

An important contribution to the sustainability of large underground hydrogen storage facilities is that existing offshore infrastructures can directly use green hydrogen instead of other energy sources for their operations. This contributes to the decarbonization of the entire offshore industry.

The North Sea is well suited for the solution due to its geological conditions and underground rock salt formations. Caverns are leached in these formations to create large storage volumes. The study assumes a total storage volume of up to 1.2 million m³ as a starting value for efficient peak coverage of offshore H2 production rates. “This storage is also necessary in the long term, because it will be an essential building block for the success of the energy transition,” explains Oltmann. “Offshore caverns can buffer the renewable energy produced in the form of hydrogen and therefore balance out the divergence between energy production and demand profiles. In this case, the proposed size of the offshore storage facility is merely a starting point.”

Teamwork for a new concept

In addition to Tractebel’s renewable energy and offshore experts, the engineering teams of DEEP.KBB GmbH and PSE Engineering GmbH, with their many years of experience, were also involved as important components in the design study. This forward-looking alliance of experts facilitated the concept’s complete development, from geology to processing equipment. This bundled know-how is the foundation for further optimizations of the offshore hydrogen hub and future H2 projects.

Image 1: Experts from Tractebel Overdick and partner companies developed the world’s first infrastructure and facilities concept that relies on offshore hydrogen caverns. Image: Tractebel Overdick

Image 2: Tractebel Overdick’s concept for an offshore hydrogen hub includes two compressor platforms and a wellhead platform (right). Image: Tractebel Overdick

Image 3: Schematic cross-section representation of the innovative offshore infrastructure and the salt caverns. Image: Tractebel Overdick

Image 4: Klaas Oltmann, Director Business Development, Tractebel Overdick GmbH.

About Tractebel

Tractebel is a global engineering company delivering game-changing solutions for a carbon-neutral future. Insights gathered during our more than 150 years of experience in energy, urban, nuclear and water projects combined with local expertise allow us to tackle complex future-oriented projects.

By connecting strategy, design, engineering and project management, our community of 5,000 imaginative experts helps companies and public authorities create a positive impact towards a sustainable world, where people, planet and profit collectively thrive.

With offices in Europe, Africa, Asia, the Middle East and Latin America, the company registered a turnover of 581 million Euros in 2020. Tractebel is part of the ENGIE Group, a global reference in low-carbon energy and services. www.tractebel-engie.com

About Tractebel Overdick

Tractebel Overdick has been active in offshore technology for more than 20 years – particularly in renewable energies. The Hamburg-based company, which employs around 50 people, has been involved in key projects in the offshore wind sector over the last ten years. The company is particularly known for the design of large DC converter platforms. Overdick has been part of the Brussels-based Tractebel Group since October 2018.

About DEEP.KBB

DEEP.KBB GmbH is an independent engineering company that designs, builds and operates underground energy storage facilities and brine/salt extraction plants in solution mining. Their expertise lies in energy storage in various geological structures such as salt formations, aquifers and depleted reservoirs. Their portfolio includes all the necessary engineering and geoscientific services. With its many years of experience and extensive expertise, the company is the right contact for project coordination, and provides comprehensive advice on all aspects of underground storage.

About PSE

PSE Engineering is a highly specialized company focusing on planning and engineering for systems technology and component supply. In the search for optimal industrial solutions, one clear principle is followed: be better. Through a broad range of technological pursuits, emerging efficiencies and technological gains are continually utilized. The development and application of new technologies in the field of hydrogen production and storage, but also the separation and long-term safe transfer of carbon dioxide keeps PSE engineers full of enthusiasm and drive. PSE strives for ambitious, unique and sustainable solutions. The daily actions and endeavors are to search for each project’s best solution. With this claim, many successful national and international projects have been carried out over many years.

Contact

Tractebel Engineering GmbH

Sabine Wulf, Head of Communications & CSR

Friedberger Straße 173

D-61118 Bad Vilbel

Phone: +49 (61 01) 55 – 0

info-de@tractebel.engie.com